Maximize Your Product Packaging Procedures With Expert Strapping Machine Service Solutions

Making best use of product packaging operations calls for a tactical technique to equipment upkeep, particularly for strapping makers. Specialist service options play a vital role in boosting efficiency and dependability - strapping machine service. By concentrating on professional analyses and safety nets, companies can address concerns before they escalate. This positive approach not only enhances productivity yet likewise minimizes expenses. However, comprehending the subtleties of these services is necessary for accomplishing the most effective outcomes. What factors should business take into consideration when choosing a company?

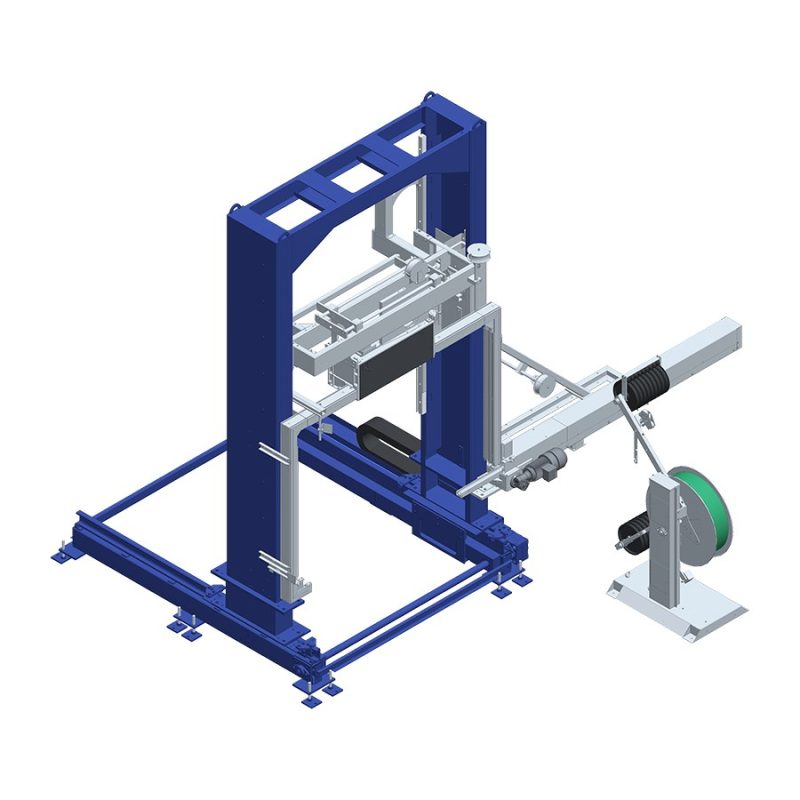

Understanding the Value of Strapping Machines in Packaging

Secret Conveniences of Expert Strapping Machine Solutions

The effectiveness and dependability of packaging operations can be considerably enhanced with professional strapping machine services. These services supply expert upkeep, making sure makers operate at peak efficiency and reducing downtime. By regularly servicing strapping devices, organizations can prevent unanticipated failings, which can interrupt production schedules and lead to monetary losses. In addition, professional service technicians possess specialized knowledge to determine possible problems early, advertising longer maker life expectancies. Improved functional effectiveness frequently converts to improved product top quality, as correctly working machines safe packages much more efficiently - strapping machine service. Moreover, such solutions can adapt to evolving packaging requirements, offering personalized options that straighten with manufacturing objectives. In general, spending in expert strapping maker services adds to enhanced workflow and raised earnings in product packaging procedures

Common Strapping Machine Issues and Solutions

Strapping makers can experience different concerns that impact their performance, especially regular imbalance troubles and band tension malfunctions. These difficulties can interfere with operations and lead to ineffective product packaging procedures. Addressing these usual problems promptly is crucial for maintaining peak machine capability.

Frequent Imbalance Issues

Imbalance problems are amongst the most prevalent difficulties faced by operators of strapping machines. These troubles can emerge from different elements, consisting of inappropriate arrangement, damage of elements, or a lack of routine upkeep. When a strapping equipment is misaligned, it can lead to unequal strap application, which jeopardizes the stability of the plans being safeguarded. Additionally, constant misalignment can lead to raised downtime, as drivers need to continually adjust the equipment for peak performance. To deal with these problems, drivers need to conduct regular assessments, confirm proper calibration, and change used parts without delay. By applying these ideal methods, services can minimize the danger of imbalance, therefore improving the performance and efficiency of their strapping procedures.

Strap Tension Malfunctions

Operators usually come across strap tension breakdowns as a substantial concern in the efficiency of their machines. These breakdowns normally materialize as inadequate tension during the strapping process, bring about loose or inefficient seals. Common reasons include worn-out tension springs, improper calibration, or debris blocking the tensioning system. In addition, an irregular feed price can contribute to uneven tension circulation, more complicating the strapping operation. To resolve these issues, normal upkeep is vital. Operators must evaluate and change used parts, adjust the tension settings according to specifications, and assure the maker is cost-free and tidy from obstructions. Implementing these options can boost maker integrity, improve strapping top quality, and inevitably optimize packaging procedures.

Selecting the Right Service Provider for Your Demands

When choosing a company for strapping maker options, what aspects should be thought about to assure peak efficiency and reliability? Initially, a service provider's experience and knowledge in the industry are important, as this warranties experience with various tools types and possible problems. In addition, reviewing customer evaluations and testimonials can supply understanding into the copyright's service high quality and responsiveness. It is additionally crucial to analyze the array of services offered, consisting of installment, repair services, and training, to ensure comprehensive assistance. Accessibility of extra parts and prompt service response times are substantial elements that influence devices uptime. Clear pricing and warranty options need to be talked about to prevent unforeseen expenses, allowing businesses to make informed choices in selecting their service company.

Preventive Maintenance: Expanding the Life of Your Devices

Preventive maintenance is crucial for maximizing the life expectancy of strapping machines. Carrying out regular evaluation methods, sticking to arranged upkeep strategies, and making certain sanitation can greatly decrease the danger of unanticipated break downs. These proactive actions not just enhance devices integrity however additionally enhance overall operational effectiveness.

Routine Evaluation Practices

Regular inspection practices are important for maintaining the performance and longevity of strapping devices, as they aid identify possible problems before they intensify into expensive repairs. These assessments ought to include examining vital elements such as the tensioning system, sealers, and motors for wear and tear. Consistently reviewing the maker's placement and performance warranties peak procedure. In addition, monitoring electrical links and hydraulic systems can protect against unforeseen downtime. Operators needs to be trained to do these evaluations and record findings to track performance fads. Carrying out a society of regular inspections not just reduces the threat of devices failing but also boosts overall performance. By prioritizing regular inspections, companies can protect their financial investment in strapping modern technology and safe smooth product packaging operations.

Scheduled Maintenance Plans

While lots of businesses concentrate on instant repairs, developing scheduled maintenance plans is vital for expanding the life of strapping machines. These plans entail regular evaluations and maintenance that help identify possible issues before they escalate into expensive failures. By adhering to a predetermined schedule, business can ensure that their equipment operates at peak effectiveness, lowering the danger of unforeseen downtime. In addition, set up maintenance can enhance useful reference safety and security by dealing with deterioration on components that could result in mishaps. Buying these aggressive procedures not only extends the equipment's life-span yet additionally enhances productivity, ultimately adding to the overall cost-effectiveness of packaging procedures. Executing a structured upkeep plan is a critical approach to protecting beneficial equipment assets.

Importance of Cleanliness

Cleanliness plays an essential function in the upkeep and longevity of strapping makers. Normal cleansing protects against the accumulation of dirt, particles, and glue residues that can prevent performance and cause premature wear. A tidy equipment operates extra successfully, decreasing the possibility of malfunctions and expensive downtime. Additionally, cleanliness prolongs the life expectancy of essential elements, such as motors and belts, by minimizing rubbing and preventing rust. Applying a routine cleaning routine is essential for operators to ensure peak performance. This aggressive method not only improves efficiency but additionally promotes a more secure working setting. Eventually, prioritizing cleanliness within packaging operations can cause considerable cost financial savings and boosted general performance of strapping equipment.

Modification Options for Ideal Efficiency

How can businesses assure that their strapping makers run at peak effectiveness? Modification alternatives play a crucial duty in improving performance. By tailoring strapping machines to details functional needs, firms can enhance tension, rate, and band size, guaranteeing compatibility with different packaging materials. Additionally, integrating innovative technology, such as automatic feeding systems and user-friendly user interfaces, enhances general capability. Businesses can likewise select between various strapping products, such as polypropylene or polyester, based upon longevity and cost-effectiveness. Normal evaluations of production needs make it possible for business to change their strapping options, adapting to changes my link in item measurements and weights. Eventually, tailored strapping makers bring about decreased downtime and increased efficiency, positioning organizations for success in affordable markets.

Measuring the ROI of Strapping Machine Providers

When assessing the return on financial investment (ROI) of strapping maker solutions, organizations should consider numerous elements that add to overall effectiveness and expense savings. Crucial element consist of the decrease in labor prices as a result of automation, reduced product waste, and boosted product packaging rate. Dependable service guarantees marginal downtime, allowing operations to maintain efficiency degrees. Furthermore, the longevity of strapping tools can greatly impact ROI; normal upkeep and prompt repair work prolong maker life-span, leading to lower substitute expenses. Improved product defense with proper strapping additionally lowers damage during transportation, additional saving cash. By analyzing these facets, firms can get an extensive understanding of exactly how professional strapping machine services straight affect earnings and functional success.

Regularly Asked Concerns

How Frequently Should I Set Up Strapping Machine Service?

Strapping equipment service should commonly be set up every 6 to twelve months, depending upon use intensity. Regular maintenance guarantees peak efficiency, extends machine life, and decreases unforeseen break downs that might interfere with product packaging procedures.

What Kinds of Strapping Products Can My Machine Make Use Of?

Strapping makers can make use of various products, consisting of steel, polyester, and polypropylene strapping. Each type offers various tensile toughness and applications, enabling services to pick one of the most suitable alternative based on their product packaging needs and requirements.

Exist Guarantees Offered for Strapping Machine Services?

Warranties for strapping device services are typically offered, varying by service provider. They usually cover parts and labor, making certain fixings or substitutes within a specified period, thereby offering peace of mind for functional dependability.

Can I Carry Out Maintenance on My Strapping Machine Myself?

Yes, upkeep on strapping devices can usually be executed by the customer. It is crucial to comply with the producer's guidelines and security protocols to guarantee efficient maintenance and avoid possible damages or malfunction.

How Do I Know When to Replace My Strapping Machine?

Indications to replace a strapping maker include constant break downs, inconsistent strapping quality, extreme wear, and outdated technology. strapping machine service. Keeping an eye on performance and maintenance costs can help figure out when acquiring a brand-new device comes to be extra cost-effective than repairing the existing reference one

The efficiency and reliability of product packaging operations can be considerably boosted via expert strapping equipment services. By on a regular basis servicing strapping makers, organizations can protect against unexpected failings, which can disrupt manufacturing schedules and lead to monetary losses. By tailoring strapping devices to particular operational requirements, firms can enhance speed, tension, and strap width, guaranteeing compatibility with different product packaging materials. Additionally, the long life of strapping equipment can substantially affect ROI; normal maintenance and prompt repairs prolong equipment life-span, resulting in reduced substitute prices. Indications to change a strapping equipment consist of regular breakdowns, inconsistent strapping quality, extreme wear, and out-of-date innovation.